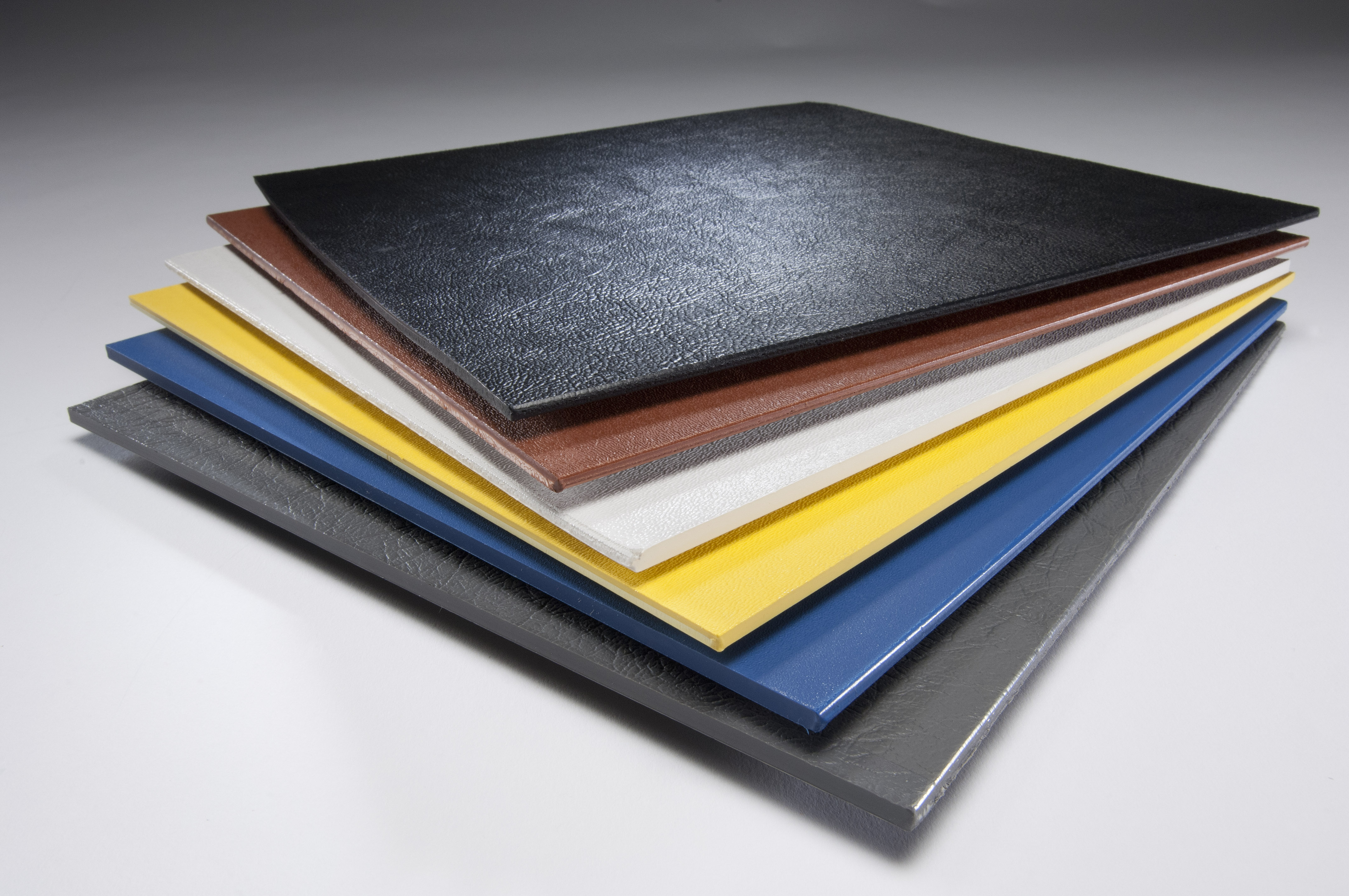

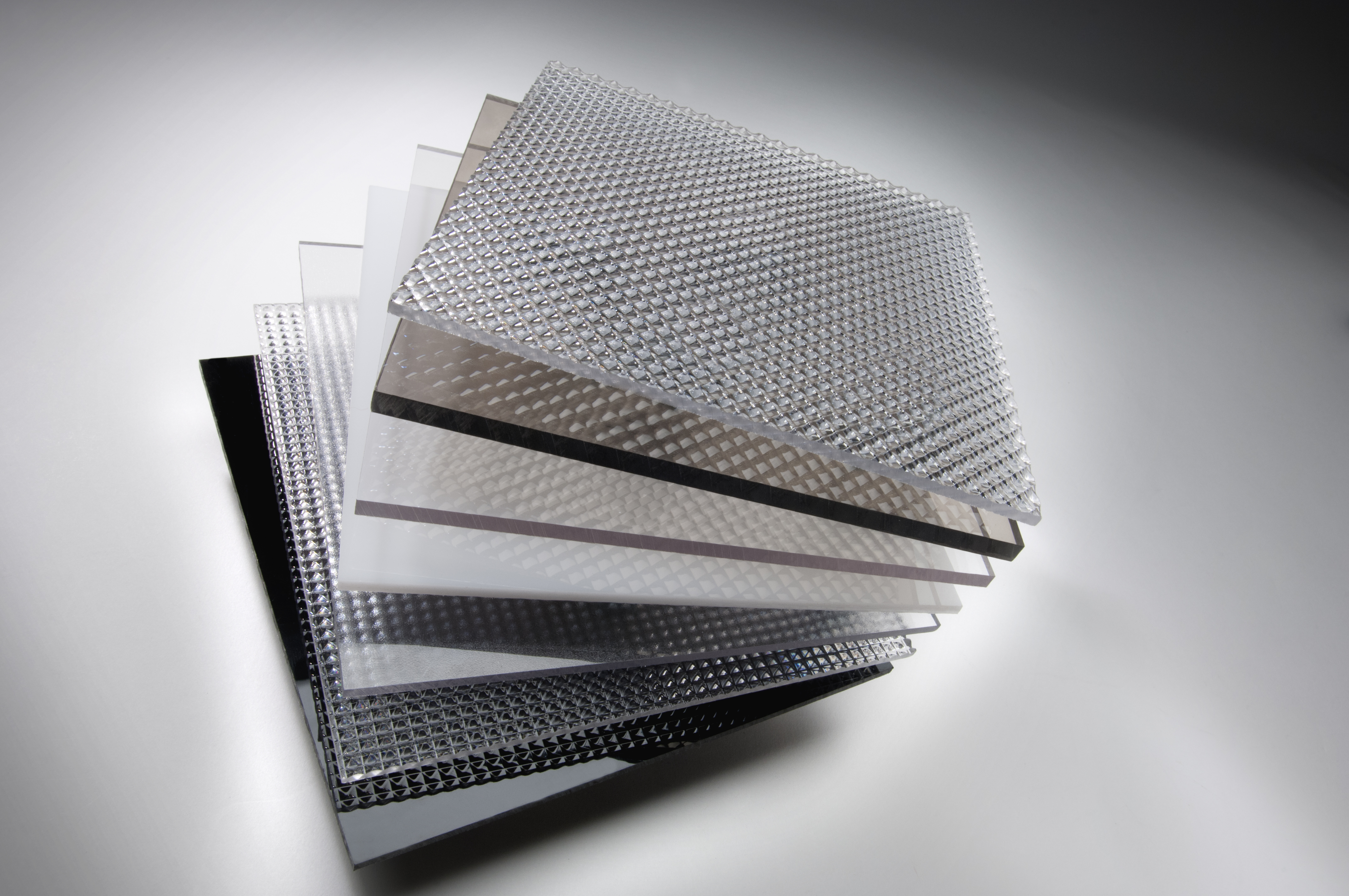

Nothing gets manufactured without having to be moved around the production facility, and most items get packaged before they are sold. Consumers want their products quickly and at the best price possible. This places demands on the machines that move and package products, requiring faster operating speeds and demanding that down time is minimized. Higher machine speed demands give plastics an edge over metal: they are lighter weight, enabling faster speeds with less energy usage. Machines that use plastic parts against metal, vs. metal on metal parts, will be quieter at higher speeds, improving the working environment for operators.

Conveying equipment is also used extensively in mining operations, carrying various types of ores, gravel, sand and other minerals out of the mine to processing areas. These environments can be highly abrasive, requiring materials that can last in challenging conditions.

Typical uses for plastics in packaging and conveying equipment are:

- Machine guards

- Star wheels

- Gears

- Chain guides

- Guide rails

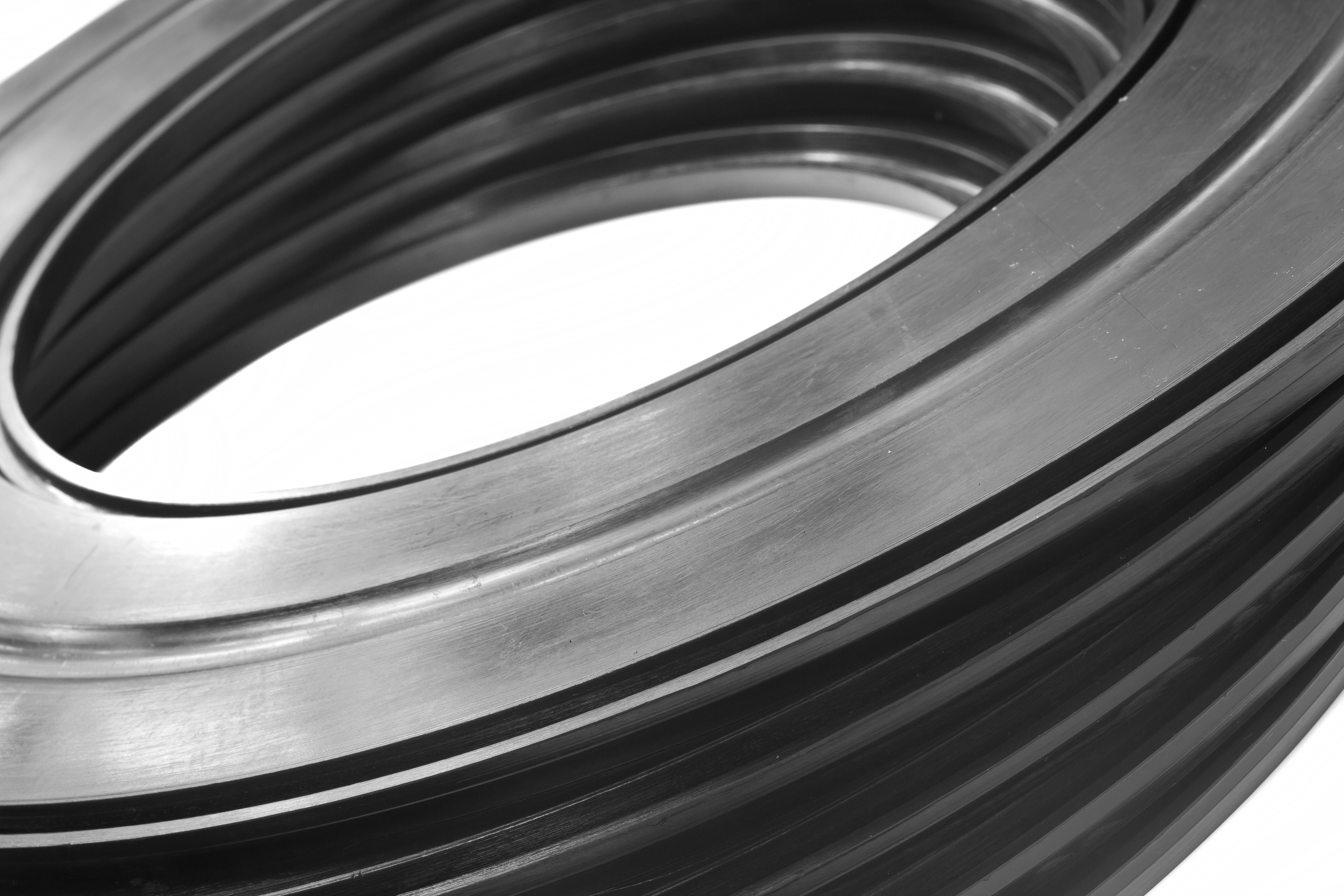

- Bearings and bushings